Andon System 4.0

Stop losing production time to missed calls and slow response.

Get instant alerts, real-time visibility, and data to prove what's really slowing you down.

Other Problems We Hear Every Week

The walking problem

Operators leaving stations to find help

"Our operators leave their stations for 10+ minutes just to find a supervisor, lead, or maintenance person. That happens multiple times per shift."

— Modular Manufacturing Facility, Florida

📊 If this happens 4× per shift:

= 40+ minutes lost daily per station

= $2,400/week in idle labor (avg.)

The radio gap

Calls that never reach the right person

"I didn't hear it. I was in the back near the compressors. The radio doesn't reach back there."

— Maintenance Tech

⏱️ The call was made. The system didn't deliver it.

No record. No proof. No way to improve.

The noise problem

Radios and intercoms lost in facility noise

"It's a loud facility. Radios aren't heard well. Intercom calls aren't audible. We've tried everything."

— Foam Manufacturing, 60K sq ft, Pennsylvania

❌ Radios get missed

❌ Intercoms disappear in the noise

❌ Phone calls go to voicemail

Stack light limits

Lights that only work if someone's watching

"I didn't see the light. I was working on the far end of the floor. There's no way to see it from over there."

— Quality Tech

⏱️ The light did its job. But lights can't walk across the plant.

22 minutes. No escalation. No notification.

The ignored call

Calls that sit unanswered until someone notices

"The call was made 25 minutes ago. No one responded. The operator just sat there waiting."

— Tier-1 Automotive, Michigan

⏱️ Without escalation:

• First responder is busy → call dies

• No backup gets notified

• No timeout rules trigger

• No one knows it's still waiting

The data black hole

No proof when management asks

"I know we're losing time, but I can't prove it. When leadership asks how much downtime costs us, I have nothing to show them."

— Operations Manager, Midwest Manufacturing

📊 Without data, you can't:

• Prove which stations need the most help

• Show leadership the cost of slow response

• Identify patterns or hold anyone accountable

• Feed your CI reviews with real metrics

The accountability gap

No record of who did what, or when

"With radios, there's no record keeping. It's all he said/she said. We can't prove anything when something goes wrong."

— Manufacturing Facility, Mississippi

📊 Without documentation:

• Can't prove response times to leadership

• Can't identify repeat issues or delays

• Can't defend your team when blamed

• Can't run effective CI reviews

Expose the Hidden Idle Time

Costing You Every Shift

* Source: Andon System 4.0 60-day free trials at North American manufacturing facilities, 2025-2026.

How We Turn Slow Handoffs Into

Fast Restarts

Press

The operator taps a station-mounted call button (e.g., “Quality”, “Maintenance”, “Materials”), instantly starting the wait timer and logging the station + reason.

Broadcast

Within one second the alert fans out to wrist pagers, SMS, email, any TV or PC monitor you choose, and flips the station's multi-colour light, so the right support team sees who needs help and where without radio chatter.

Escalate

If the call isn't attended within the limit you choose (90 seconds, 5 minutes, or any window you set), Andon System 4.0 automatically escalates to a backup team, supervisor, or plant manager, ensuring no request is ever overlooked.

Attend

When the job is done, the responding team clears the call on the station-mounted call button. The wait timer stops, and an “all clear” instantly updates every pager, screen, and light.

Quick Setup,

No Downtime

This layout shows how the Andon System 4.0 is deployed across the production floor.

-

Every time an operator walks away to find help, you lose 10+ minutes of production. Station-mounted call buttons let them signal for Materials, Maintenance, or Quality with one tap, while staying at their post. One press starts the clock; one press clears it when the job's done.

-

"Someone came, but I don't know how long it took to fix." Sound familiar? The optional yellow button logs the exact moment help arrives, so you can measure wait time AND repair time separately. Every call logged, every response tracked, every delay documented.

-

When a call goes unanswered, everyone should know, not just the operator waiting. Turn any TV or monitor into a live status board showing open calls, wait times, and who's responding. No special hardware. Visibility creates accountability.

-

Radios get missed. Phone calls go to voicemail. Intercom announcements disappear in the noise. And in plants where personal phones aren't allowed on the floor, there's no fallback. Wrist pagers vibrate and flash, so your team knows the moment they're needed, whether they're on a forklift, in a closed cab, or across the plant.

-

What happens when the first responder doesn't answer? Calls auto-escalate via SMS or email to backups, supervisors, or plant managers, based on rules you set. No call falls through the cracks. Works from any phone, anywhere.

-

In high-noise zones, sound isn't enough. Multi-color stack lights show at a glance which stations need help and what type of support is required. Visible from across the floor. Supervisors see the problem before they hear about it.

-

How many times does the wrong person show up because the call didn't have enough detail? Custom issue lists and notes let operators explain what's wrong, so the right person arrives with the right tools the first time. Access from any computer, tablet, or phone.

-

Why wait for an operator to notice a problem? PLC integration triggers alerts automatically when machines detect faults, temperature spikes, or material shortages. Before the line stops. Proactive response, fewer surprises.

-

We'll ship the hardware, walk you through setup (under 60 minutes), and train your team. All at no cost. Run it live for 60 days. If it doesn't deliver, return it. No fees, no hassle, no awkward conversations.

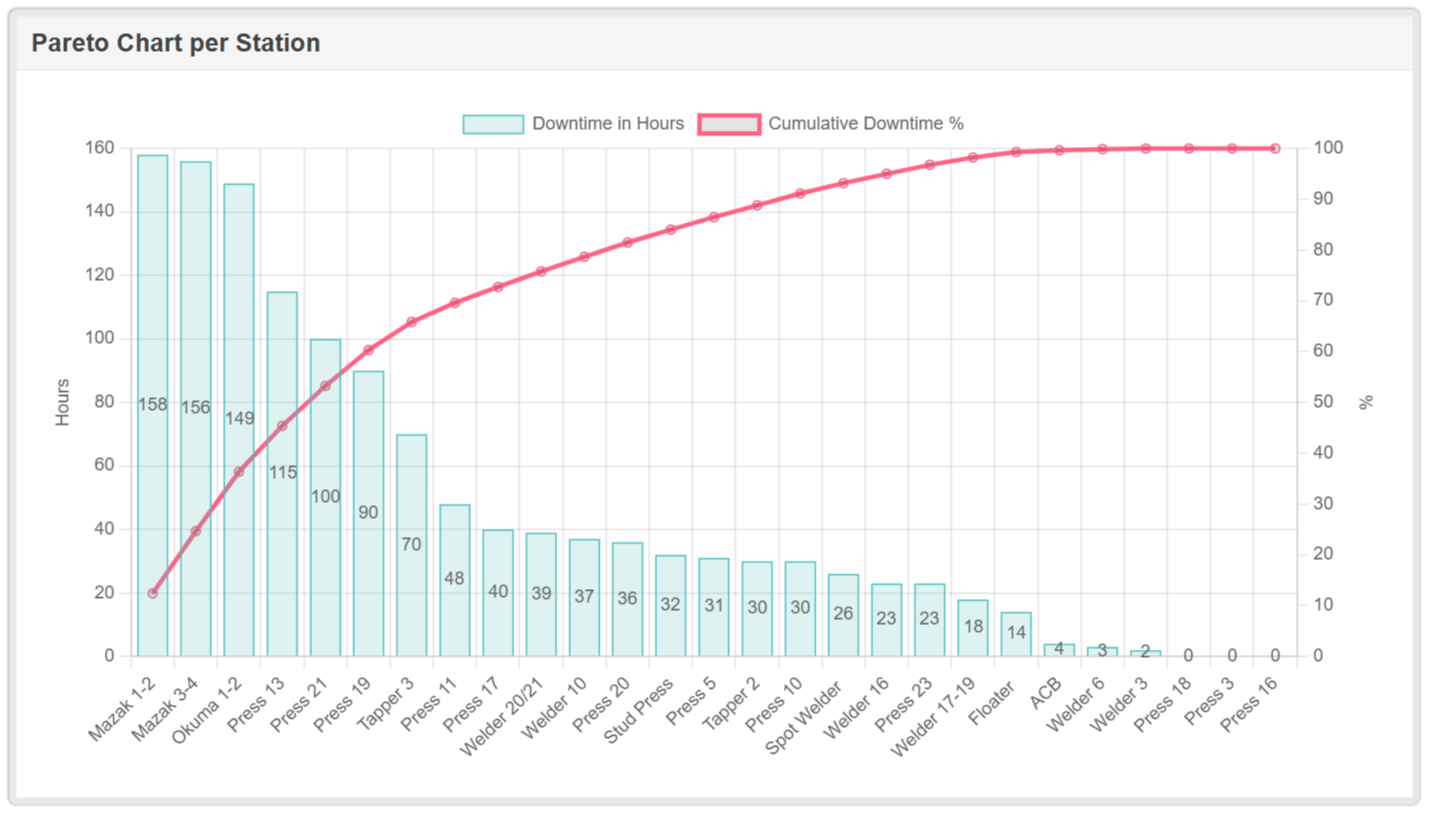

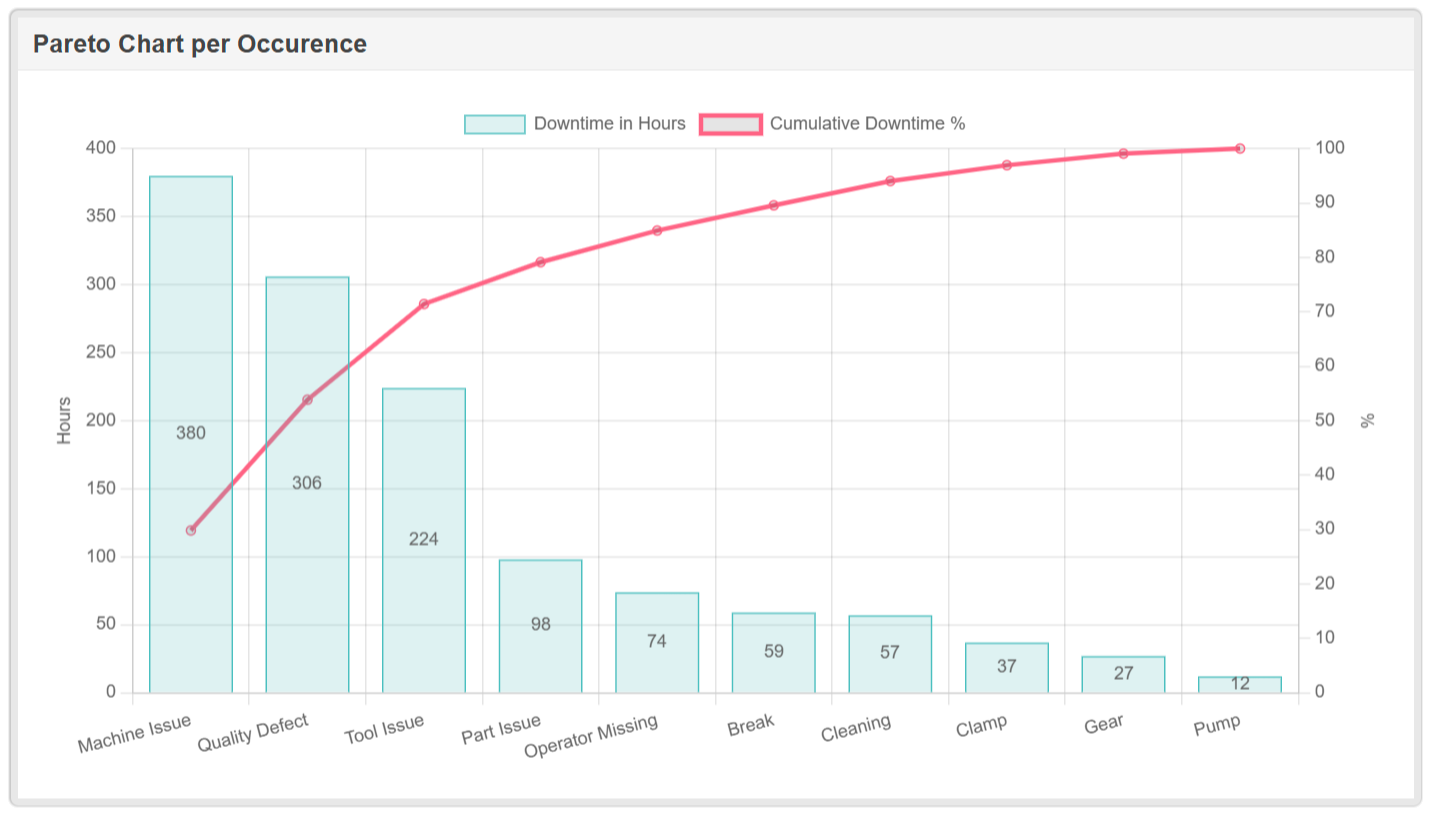

See the Bottlenecks,

Then Eliminate Them

Station-level and occurrence-level Pareto charts expose the handful of hotspots driving most delays. Export the data (or stream it live) to your BI, MES, or any third-party tool for deeper analysis.

Why Plants Trust

Andon System 4.0

Field-Tested in 1,000+ Plants

From Tier-1 automotive to medical device assembly, food & beverage lines to heavy machinery manufacturing, Andon System 4.0 has been stress-tested across North America.

Plug-and-Play Setup & Easy to Adapt

No complex installs. Setup takes under an hour with remote support. Adjust everything in-house as your processes evolve.

Try It FREE for 60 Days, Zero Risk

We'll send the hardware, help you launch it quickly, and let you run it live for 60 days. If it doesn't deliver, just send it back. No cost, no hassle.

ROI in ≤ 45 Days

The average trial line recovers the full hardware cost within six weeks, purely by cutting wait time. Most plants hit payback before the 60-day trial even ends.

Common Concerns,

Answered

"We don't have time to implement a new system"

Setup takes under 60 minutes during lunch or a scheduled stop. Most plants are live on Day 1 with minimal disruption.

"Our budget is tight right now"

The 60-day free trial means zero upfront cost. Average ROI hits in ≤45 days. Most plants recover hardware cost before the trial ends.

"We already have radios / stack lights / MES"

Radios get lost in noise. Stack lights only work if someone's watching. MES tracks machine state, not how long your operator waited for help. Andon System 4.0 fills that gap.

"We need to evaluate other options first"

We encourage comparison. But with our no-risk 60-day trial, you can test Andon System 4.0 in parallel: real data, real results, zero commitment.

A Trusted Partner

to the Best

Hidden Wait Time Exposed: Six Plants, One Tool

Different products, same outcome: actionable data in 48 hours, payback well before the free trial ends.

Frequently Asked Questions

-

How is Andon System 4.0 different from stack lights or radios?Stack lights show a problem. Andon System 4.0 shows the lost minutes until it's fixed, logs the reason code, and escalates automatically so no call is missed.

-

What problem does this solve that our MES dashboards don't?MES and OEE dashboards track machines. Andon System 4.0 tracks the human wait time between problem and response: the biggest hidden cause of lost output.

-

Which manufacturing environments does it work best in?Assembly, machining, plastics, food, and heavy-vehicle plants already run Andon System 4.0. Any line where people wait on support is a fit.

-

Does installation interrupt production?Typical installation takes under 60 minutes during a scheduled stop or lunch break. No PLC edits required.

-

Will operators need special training?Training is a 5-minute toolbox talk: "press the red button for help, press the green button when finished." Most teams use it confidently on Day 1.

-

What call types come standard?The three most-used labels are Materials, Maintenance, and Quality but you can relabel the buttons to whatever you need.

-

Can we customize which team receives which call type?Yes. Route Maintenance calls to maintenance techs, Quality calls to QC, Materials to material handlers. Each call type can have its own recipient list, escalation path, and timeout rules.

-

Do we need Wi-Fi on day one?No. The RF mesh runs standalone. Wi-Fi or Ethernet is only needed if you want live dashboards around the plant.

-

What if our network goes down? Do alerts still work?Yes. Button-to-pager traffic is local RF and continues even if the LAN or cloud connection is offline.

-

Can we start with one line and expand later?Yes. Most plants start with a single high-priority line during the 60-day trial, then roll out plant-wide once they see results. The system scales from 1 station to 500+ without architectural changes.

-

How fast will we see actionable data?Plants surface their top wait time bottlenecks within the first 48 hours of the 60-day free trial.

-

Is the 60-day free trial really no-risk?Yes. We ship the hardware and guide your team through remote setup and training, at no cost. If you're not convinced by Day 60, we help you return the kit. No fees, no obligations.

-

Do you provide OEE dashboards?Andon System 4.0 focuses on wait time and response time. You can export CSV files or stream data to your OEE or BI system in real time.

-

Do you offer virtual buttons for computers and mobile devices?Yes. Virtual buttons can be accessed from any computer, tablet, or smartphone, allowing operators to send detailed messages and select from custom incident lists. This advanced feature is ideal for operations that need more context than standard call buttons provide.

-

Can Andon System 4.0 integrate with PLCs for automatic alerts?Yes. PLC integration allows machines to automatically trigger calls when specific conditions are met. No manual button press required. This enables proactive maintenance alerts, quality holds, and material shortage notifications directly from your control systems.

-

Is there a subscription or per-user fee after purchase?No subscriptions or per-user fees. Hardware and license are a one-time cost. Only optional SMS and email alerts require a low annual subscription.

-

What support do we get once we purchase?Lifetime customer and technical support and free firmware updates. Refresher training is available on request.